- Home

- Products

- Services

- Product concept development

- Engineering

- Design for manufacturability

- Regulatory services

Read more - Material selection and formulation

- Prototyping

- Testing and validation

Read more - Production process development

- Custom tooling

- Manufacturing

- Finishing operations

- Assembly

- Packaging

- Private labeling

- Sterilization

Read more

- Resources

- Careers

- Search

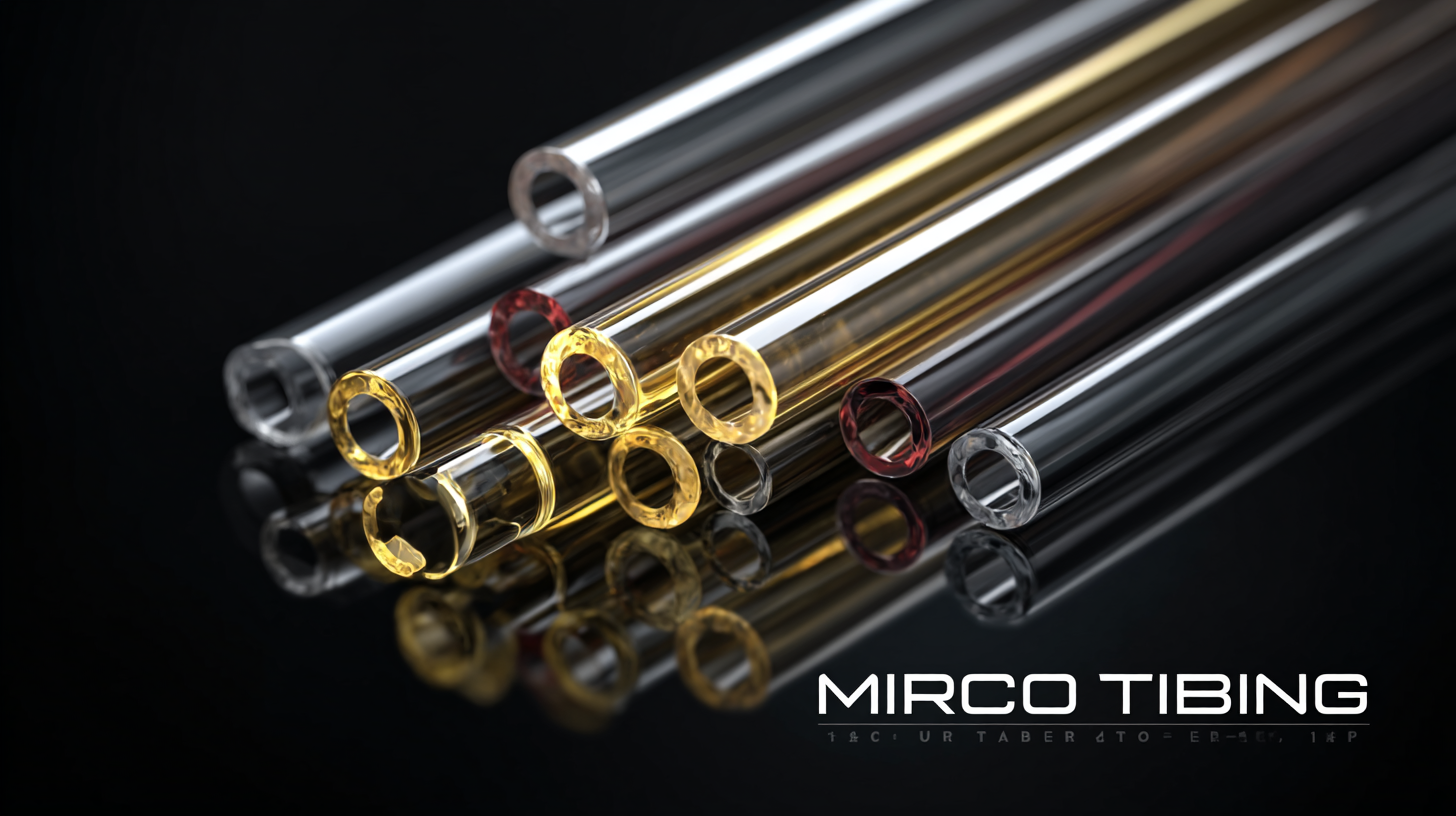

How to Choose the Best Micro Tubing for Optimal Performance and Cost Efficiency

In the fast-evolving world of fluid transfer and precision applications, the choice of micro tubing is critical for achieving optimal performance and cost efficiency. According to a recent market research report by Grand View Research, the global micro tubing market is projected to reach USD 1.21 billion by 2025, driven by increasing demand in the medical and industrial sectors. As industries strive for higher efficiency and reduced production costs, selecting the right materials and specifications for micro tubing becomes imperative. With a variety of options available—including different polymers, diameters, and wall thicknesses—understanding the detailed technical parameters of micro tubing is essential for making informed decisions. This blog aims to guide you through the vital aspects of choosing the best micro tubing, ensuring you optimize both performance and cost-effectiveness in your specific applications.

Understanding Micro Tubing Materials: A Deep Dive into Specifications and Applications

When selecting the best micro tubing for specific applications, understanding the materials used is crucial for achieving optimal performance and cost efficiency. Micro tubing is utilized in various industries including irrigation, biomedical technology, and advanced manufacturing. For instance, in sustainable irrigation systems, the use of specialized micro tubing can significantly enhance water efficiency and productivity, particularly in the cultivation of crops such as blackgram, which plays an essential role in food security. The right material choice can lead to improved fluid dynamics and longevity, making it vital for agricultural applications where resource conservation is paramount.

In biomedical applications, piezoelectric micro-tubes exemplify the advancements in micro tubing technology. These tubes are designed for nanopositioning, fiber alignment, and high-resolution imaging, showcasing how material specifications can affect performance in sensitive environments. Similarly, innovations in manufacturing processes, such as the development of double-lumen extrusions and micro-drilling techniques, underline the importance of precision and material selection in creating effective micro tubing solutions across different sectors. By diving into the specifications and functions of various micro tubing materials, one can identify the best options that not only meet technical requirements but also contribute to overall cost savings in operations.

Evaluating Diameter and Wall Thickness: Key Factors for Performance and Efficiency

When selecting micro tubing for specific applications, evaluating the diameter and wall thickness is crucial for achieving optimal performance and cost efficiency. The diameter affects the flow rate and pressure characteristics of the tubing, which can be critical in applications requiring precise fluid delivery. A larger diameter generally allows for higher flow rates, but it can also increase the system's overall weight and cost. Therefore, it's essential to strike a balance between the needed flow rate and the constraints of the application.

Tips: Consider conducting flow simulations to identify the ideal diameter for your system. This can help you visualize how different sizes will impact performance and assist in making informed decisions on tubing specifications.

Wall thickness, on the other hand, significantly influences the tubing's durability and resistance to pressure. Thicker walls can provide better protection against burst pressure, making them suitable for demanding environments. However, increased wall thickness can also lead to higher material costs. It's important to assess the operational conditions to determine the appropriate wall thickness that aligns with both performance requirements and budget constraints.

Tips: Use material selection guidelines to understand how wall thickness interacts with factors like temperature and chemical compatibility. This knowledge can enhance both efficiency and longevity in your micro tubing applications.

Micro Tubing Diameter and Wall Thickness Evaluation

The Role of Micro Tubing in Emerging Technologies: Trends Shaping 2025 and Beyond

Micro tubing is playing a crucial role in the evolution of emerging technologies, particularly as industries focus on efficiency and sustainability. As we approach 2025, the integration of micro tubing in fields such as medical devices, water management, and fuel systems is expected to drive innovation. The lightweight and versatile nature of micro tubing allows for enhanced performance in applications where space and weight are critical factors. This trend aligns with the increasing demand for compact solutions across various sectors, leading to more streamlined processes and reduced operational costs.

Tips for choosing the right micro tubing include considering the material compatibility and the fluid dynamics involved in your application. Ensure that the selected tubing can withstand the necessary pressure and temperature ranges while maintaining flexibility. Additionally, evaluating supplier options for reliability and performance history is essential to achieve optimal results.

As trends continue to shape the landscape of technology and industry, keeping an eye on advancements in micro tubing will be vital for businesses aiming to remain competitive. Engaging with startups focusing on innovative water management solutions can open new avenues for collaboration and growth, enhancing your operational effectiveness in the long run.

Cost Analysis: Balancing Quality and Affordability in Micro Tubing Selection

When selecting micro tubing for your projects,

cost efficiency plays a vital role in ensuring you get the best value without compromising quality.

To achieve this balance, it's important to start with a thorough cost analysis.

Begin by evaluating the various materials available, such as polyethylene,

nylon, or PTFE,

each offering different levels of durability, flexibility, and resistance to environmental factors.

By understanding the specific requirements of your application, you can narrow down your options and focus

on those that provide the best durability for the price.

Additionally, consider the total cost of ownership

when making your selection. This includes not only the initial purchase price but also installation costs,

maintenance, and potential downtime if tubing fails. Investing in high-quality micro tubing may have a

higher upfront cost, but it can lead to savings in the long run through reduced replacements

and maintenance efforts. Always take the time to compare suppliers

and seek out those who provide a good blend of cost and quality,

ensuring your choice meets both your budgetary constraints and performance needs effectively.

Best Practices for Sourcing Micro Tubing: Vendor Selection and Quality Assurance Strategies

When sourcing micro tubing for your projects, vendor selection and quality assurance are critical components that directly impact performance and cost efficiency. According to a report by Grand View Research, the global micro tubing market is projected to grow at a CAGR of 7.4% from 2022 to 2030, highlighting the increasing demand for high-quality micro tubing across various industries, including medical devices and aerospace. Choosing a vendor with a proven track record in producing micro tubing that meets industry standards can significantly enhance your project outcomes.

Quality assurance strategies should be implemented to ensure the micro tubing you select adheres to stringent performance criteria. A study by the International Organization for Standardization (ISO) indicates that companies that prioritize quality control are 20% more likely to achieve long-term customer satisfaction. To guarantee that the micro tubing is fit for purpose, consider vendors that utilize ISO-certified quality management systems and provide detailed product specifications and certifications. This not only ensures reliability but also aids in mitigating risks associated with material failures and performance inconsistencies. By prioritizing these best practices in vendor selection and quality assurance, you can optimize your micro tubing choices to achieve both performance excellence and cost efficiency.